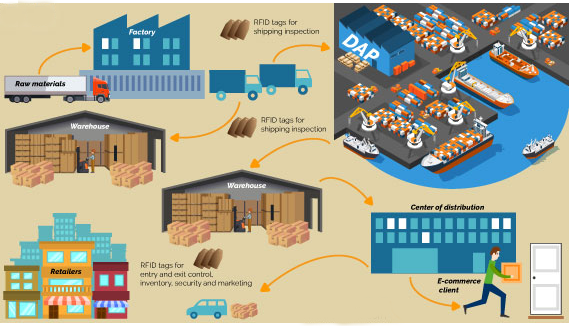

The RFID solutions for warehousing logistics gather a wide range of RFID solutions. You can find them in almost every business process. For example, from tracking returnable transport units in the supply chain to retail inventory management. The automatic control of logistics is one of the major challenges nowadays and RFID technology is an essential tool for that.

AUTOMATIC MANAGEMENT WITH RFID TECHNOLOGY

Automatic management with RFID technology has the capacity to significantly improve global logistics chains. And it also increases the overall efficiency of the identification processes. Major retailers and their suppliers are already tagging pallets, cases and other returnable transport items(RTIs) like plastic crates used for fresh foods. On the other hand, logistics also is the control of retailers inventory. That’s why logistics is so wide and complex.

BENEFITS OF RFID SOLUTIONS FOR LOGISTICS

As we already have said, the definition of logistics gets together a lot of business processes. Below you can find the main benefits of automatic control of logistics with RFID technology.

For Manufacturers

- Better customer service

- Process optimization

- Faster billing

- Optimization of shipping papers

For Distributors

- Higher shipping accuracy

- Faster and more reliable deliveries

- Better traceability

- Greater cost savings

For Retailers

- Faster processes

- Less out of stocks

- Faster processes

- Better customer service

COMPANIES WITH RFID LOGISTICS SHOW GREATER COMPETITIVENESS

The digitization of all processes optimizes the speed, efficiency and profitability of all processes by improving:

- inventory management,

- warehouse,

- transport,

- procurement,

- asset control,

- staffed,

- and exchange with suppliers.

As well as the realization and management of metrics to analyze and execute continuous improvement strategies. The system that makes this leap to the digitization of all processes possible is RFID logistics.

WHAT IS RFID LOGISTICS

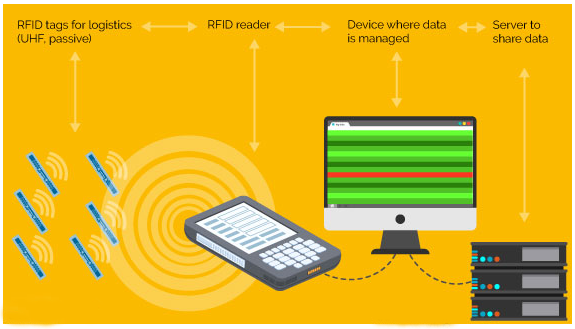

In a very short way, we will define that RFID systems and solutions allow us to identify an object with a unique code for its exact real-time traceability, being able to read these codes an masse and without direct line of sight at different distances, which can range from the contact to the 10cm (HF RFID), to the 12m (UHF RFID with passive tags), up to 30m (UHF RFID with active tags).

The update of logs in databases in real-time, at the same time, that the event happens. RFID technology also allows to automate logistics processes without human intervention, update the data and share it within the system and with external partners at high speed and with total precision.

THE APPLICATION OF RFID TECHNOLOGY FOR LOGISTICS

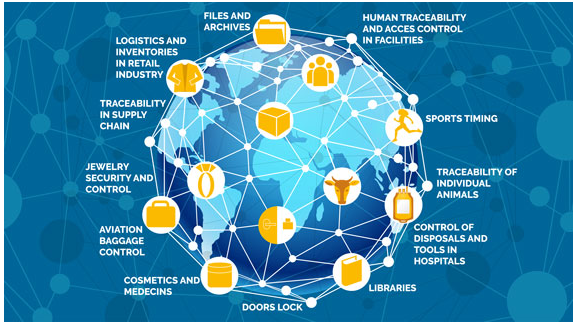

In Spain, 52% of RFID tags consumed are used for RFID systems in logistics.1 The rest is applied in access control, in control of machinery and consumables of the health industry and also in hospitality, in product safety in retail business, in sports and production timing, or in the improvement of the end customer experience, among others. In addition, RFID tags can meet various traceability, security and marketing needs.

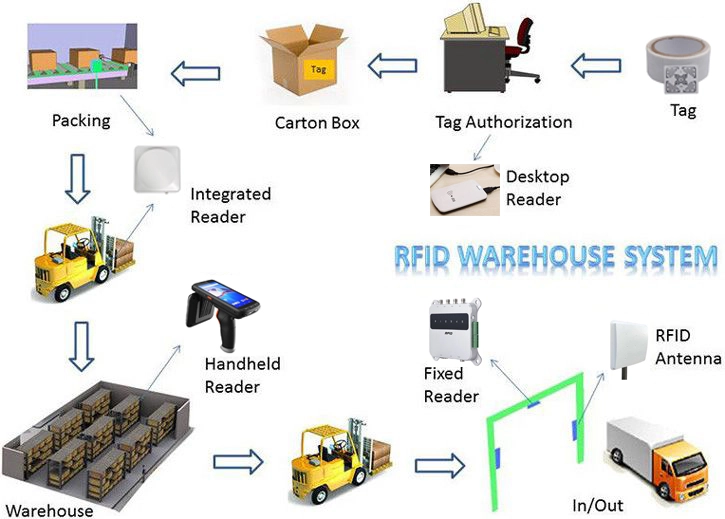

WORK FLOW OF RFID WAREHOUSE MANAGEMENT

- Goods storage, palletizing: detecting the bar code information on each cargo, each group of goods bar code information to form a data packet, to achieve the pallet as a unit to manage the goods.

- Pallet space allocation: after completing the palletizing, the warehousing management system will automatically allocate a cargo space for the pallet; at the same time, the RFID forklift reader reads the RFID label to obtain the goods space that the pallet should be placed, and instruct the forklift operator to place it in the correct position.

- Pallet operation: after the forklift puts the pallet on the space, read the location information and check whether the pallet has been placed in the correct position. Meanwhile, the forklift operator will update the location information in the RFID label.

- System management: system management includes warehouse information data statistics, cargo inventory, pallet information adjustment, information query, etc.

- Picking off shelves: when an order is received, the system will assign work to the designated forklift, and the forklift reader will receive the task. At this time, the forklift reader will update the information in the location tag.

- Goods-out: after the forklift removes the specified pallet, the system will instruct the forklift to transport the pallet to the exit. After arriving at the exit, the RFID fixed reader will read the pallet RFID label information, and upload the information to the server.

ADVANTAGES OF RFID WAREHOUSE MANAGEMENT

- The use of RFID labels can improve the accuracy of warehousing management.

- System runs through the storage, warehousing, inventory, logistics, etc.

- RFID middleware has super expansibility and facilitates the docking of various systems.

- Realizes the unified management of “goods-goods location-personnel-tasks”

Yiiro manufactures many RFID tags and RFID reader antennas for every warehousing logistics process. We also customize these labels to provide the RFID solution that fit the customer’s need. Just contact us and let’s talk about what do you need.