I. Project Background

With the development of enterprises and the increase of efficiency, the production of goods is becoming more and more diversified, and warehouse management has become a top priority for enterprises, because it is not only related to the efficiency of the entire warehouse operation, but also related to the ability to bring viable economic profits for enterprises. The traditional warehouse management has not adopted standardized management, the information of incoming and outgoing warehouse is still recorded by the original paper documents, and the process of goods sorting and distribution still adopts manual checking and handwritten marking, which is under the operation efficiency and prone to manual errors, resulting in poor information transmission, lagging management, and the effectiveness and timeliness of work is not guaranteed.

II. RFID Technology Introduction

Radio frequency identification (RFID) technology is a wireless communication technology, which can identify specific targets and read and write relevant data in the range of a few centimeters to a dozen meters according to the application needs, and no need to establish mechanical and optical contact between the identification system and the target.

RFID technology can identify objects in motion effectively and quickly, not only for long-distance reading, but also for batch reading to ensure the convenience and efficiency of production data.

RFID technology allows for penetration and accessibility, penetrating through non-metallic or non-transparent materials such as paper, wood and plastic, and enabling penetrating communication, making it suitable for use in warehousing and warehousing environments.

RFID tags are resistant to dirt and corrosion, including vibration and water.

III. Project solution introduction

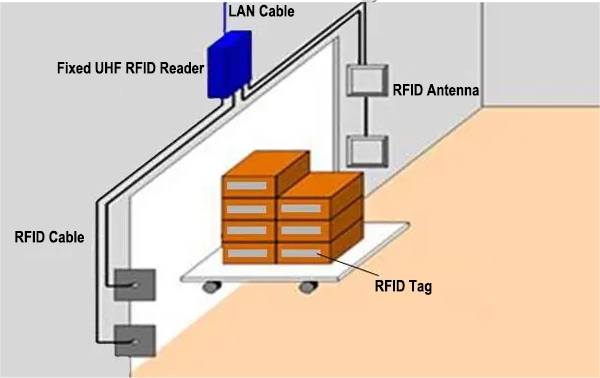

RFID warehouse goods in and out management is based on UHF RFID technology, with RFID handheld terminals, Fixed RFID readers, RFID tags, RFID antennas and other carriers, for long-distance automatic identification and collection of data in various operational aspects of warehouse materials such as incoming, outgoing, transferring, moving, inventory count, etc., to ensure the accuracy of data in all aspects of warehousing, to grasp the real data of inventory in a timely manner and improve the efficiency of warehouse management.

3.1. Data binding

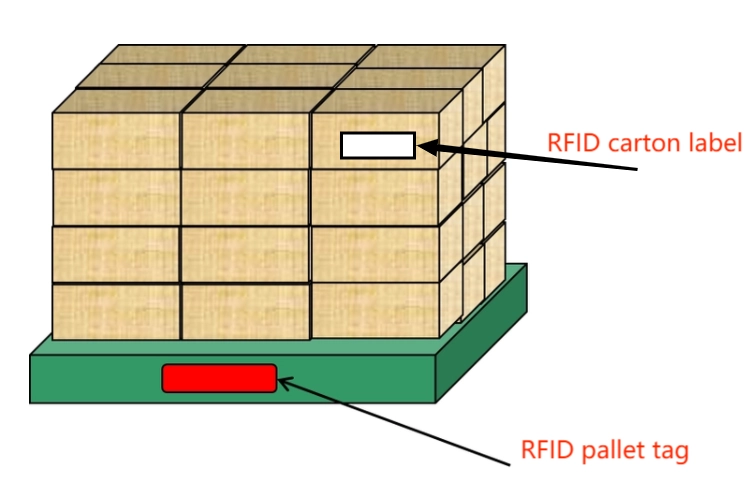

RFID tag data binding is performed in the process of raw material procurement into the warehouse or goods in production. Write the relevant information of the goods into the UHF RFID tags, such as procurement information, production information, specifications and other business-defined information, and then fix the tags on the goods or placed on the pallets of goods by various means, so as to complete the initial goods information binding, making the goods with a unique identification code, thus creating “one item, one code”.

3.2. Data Acquisition

Scene 1, inbound and outbound identification: Install UHF RFID reader & antenna at the warehouse portal, when the goods are moved inbound and outbound through the warehouse gate, the reader installed at the warehouse portal will automatically collect the information of RFID tags on the goods and RFID tags on the pallets, and transmit the collected information directly to the backend data center to complete the inbound scanning binding, realize automatic scanning counting, automatic binding, no need manual intervention, and automatically complete the inbound and outbound operation.

Scene 2, goods inventory: The goods in storage are classified according to category and model, and the staff use the UHF RFID handheld reader in their hands to scan and identify the items in batch according to the model, and then put them into the corresponding position on the warehouse shelves. In daily inventory, the staff use the RFID handheld inventory terminal to scan the goods on the shelf in batch, and then finish the inventory count quickly.

IV. Advantages of RFID warehouse management solution

4.1. Convenient to track goods information quickly: Login to the backend system, you can quickly search the specific information of the goods according to certain conditions of the goods, and can check the incoming time, outgoing time, operator, order information, etc. to realize the process tracking of the goods.

4.2. Reduce labor, improve efficiency: change the traditional manual in/out operation mode, reduce labor costs, reduce the chance of error and improve management efficiency, centralize data information, update warehouse information in a timely manner, thus improving business efficiency.

4.3. Ensure information real-time and accuracy: After the staff make inbound and outbound operations on the items through RFID handheld inventory terminal, the data will be uploaded to the system database in time, which can realize the data summary of the item information and provide a variety of data reports to make multi-angle analysis on the inbound situation, outbound situation, return situation, demand statistics, etc. to provide accurate data basis for enterprise decision-making.

If you want to discuss more about RFID warehouse inventory solution , welcome to contact with our specialists.