RFID technology is a non-contact automatic identification technology, with non-contact, long-distance, fast reading multiple tags and other characteristics, significant application in the field of tool management, able to realize the fine control of the work apparatus, to help prevent accidental loss of tools resulting in the emergence of security risks.

Ⅰ. Current status of tool management

(1) Difficulty in finding maintenance tools and lost tools, and extremely low efficiency

(2) 2D code or barcode can not meet the existing tool control

(3) Tool status information cannot be supervised in real time, and the tool management accountability system is not perfect

(4) Traditional tool management approaches are not effective in controlling potential threats to FOD.

Ⅱ. RFID intelligent tool management system

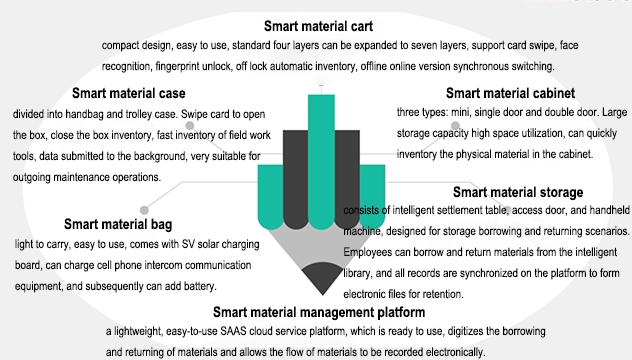

Using RFID technology, put the tools with RFID tags into the tool carts, tool cabinets, tool boxes, tool kits or tool rooms that are specially customized and equipped with RFID readers to realize tool borrowing, returning, locating, positioning and inventorying. Different hardware equipment solutions are suitable for different operating environments!

1、Marking of tools with RFID tags

Different tools and equipment need different shapes of electronic tags for identification.

2、RFID smart tool cart

RFID smart tool cart adopts RFID technology and consists of self-developed control system and multiple positioning antenna units, which can realize the accurate control of tool positioning to the layer, significantly improve the accuracy and efficiency of work apparatus management, effectively prevent and reduce the loss and theft of work apparatus, simplify the registration process of work apparatus in and out of the warehouse, avoid the lack of inventory or management negligence, etc. It can meet all kinds of tool storage in the aviation industry It is an intelligent device that can meet the needs of all kinds of tool storage in the aviation industry and realize the information management of tools and the fine control of FOD in the aviation industry.

3、RFID smart tool cabinet

RFID smart tool cabinet is an EPC C1 G2 (ISO18000-6C) protocol, the use of Internet of Things RFID sensing technology, as well as edge computing, communication networks, cloud platforms, artificial intelligence algorithms and other cutting-edge technologies to achieve the full life cycle management of safety tools from procurement, distribution, use, inspection, to end-of-life, to achieve the refinement, intelligence, and wisdom of the aviation industry tool management.

4、RFID smart toolbox

RFID smart tool box using RFID technology, through the software makes the storage box automatically manage the tools with RFID tags stored in the box. It realizes the scientific and automatic management of tools, which can significantly improve the accuracy and efficiency of tool management.

5、RFID Smart Toolkit

RFID smart tool kit is suitable for outdoor operation and maintenance scenarios, the product uses UHF RFID technology to achieve batch self-service inventory, equipped with a 5-inch touch screen for easy borrowing and returning operation. Simple and beautiful appearance, stable reading and writing area, controllable range, data transmission through 4G, is a high-performance, easy to use RFID tool work kit.

6、RFID tool entry and return workstation

Confirm the user’s identity information, record the user’s information on borrowing and returning tools, RFID tool label production and classification, and other service information.

7、RFID handheld terminal

Through RFID handheld terminal, it conducts non-contact inspection inventory of all tools on the shelf of the tool storage room and obtains status information of all tools on the tool shelf, including the number of tools, tool location and other information.

8、RFID channel access control

RFID detection channel access control is arranged at the door of the tool storage room, when personnel carry tools through the channel access control, the channel access control can automatically determine whether to allow the passage, if the tool is judged to be not for the normal borrowing and returning procedures to provide sound and light alarm to warn and record.

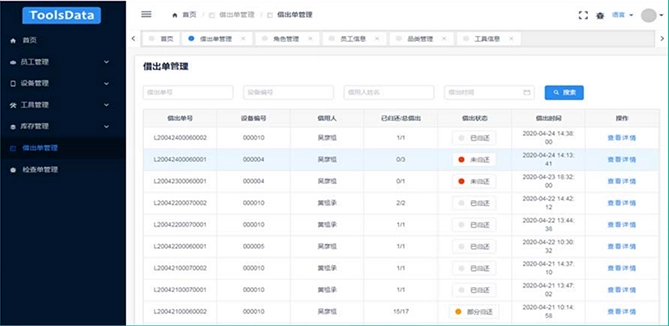

Ⅲ. RFID tool management system platform

Ⅳ, Values based on RFID intelligent tool management system

1. Intelligent control of maintenance tools is realized, and tools are controlled and traceable.

2. Real-time control of tool movements, avoiding the security risks caused by lost tools.

3. Fully automatic tool in/out management, greatly improving the efficiency of tool lending and returning.

4. Safety and security, traceability to the person, avoid disputes and reduce the loss of assets.

5. Real-time collection of tool usage data in the background, scientific analysis and report generation.